Register your thermal oxidizer to receive free maintenance tips and new product updates

Why choose TANN as your technical service experts?

Save Money

TANN’s preventive maintenance program is proven to save you money. PMs reduce equipment downtime and keep your plant running at maximum efficiency.

Safety

Our technicians have the experience and training to validate all the safety interlocks throughout the system. At TANN safety is our #1 goal, for our people, our equipment, your people and your facility.

Compliance

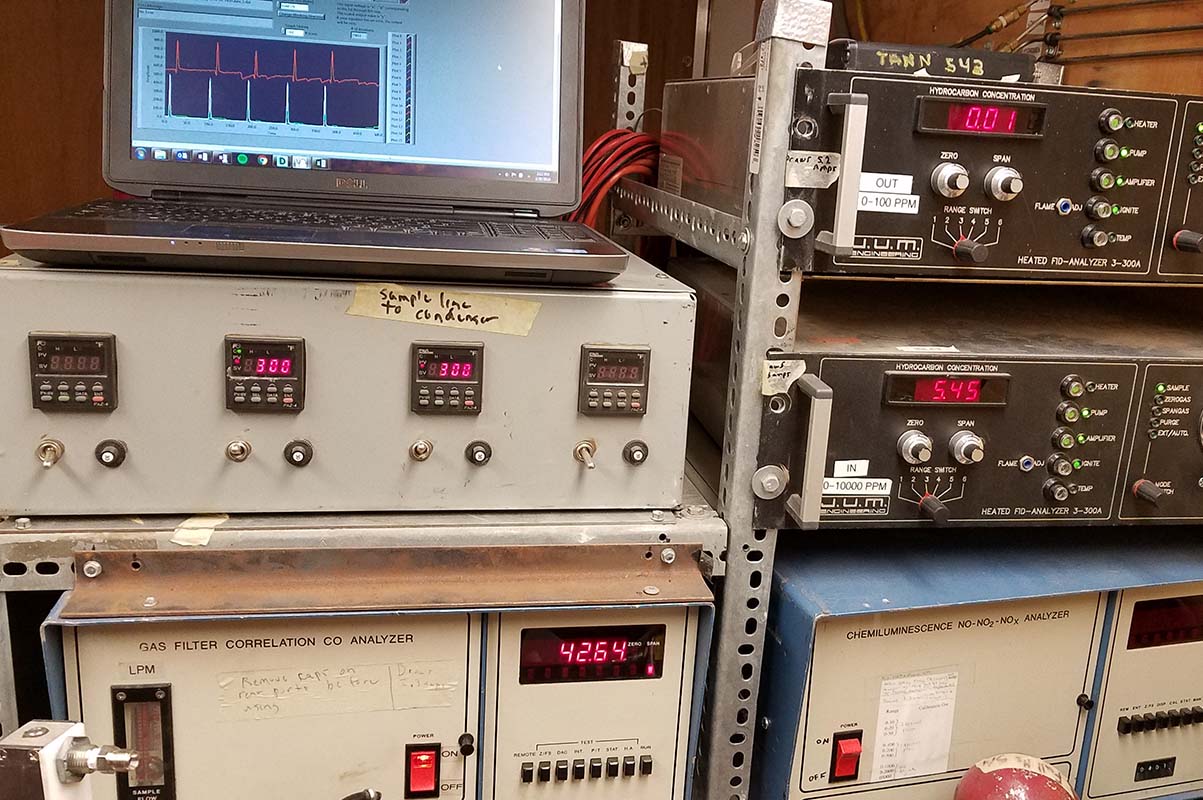

Routine maintenance can prevent non-compliance issues and possibly eliminate regulatory fines. We can provide the repairs or modifications required during scheduled outages to put the system back into compliance. We even have our own testing equipment to validate the repairs.

Equipment Life

Annual PMs have proven to extend the life of the equipment thus lowering the cost of ownership.

Availability

TANN has 24/7 technical support to help troubleshoot any issue. If needed our technicians can be onsite within 24 hours. Let us maintain your equipment, so you can focus on your business.

Technical Services

Our trained technicians can help with any oxidizer problem you may have. Whether it's burner related issues, fan balancing or just routine maintenance, our service team can help keep your equipment running at optimum performance.

Ceramic Media

TANN will provide the expertise for media replacements in systems with fouled or damaged media. Providing a turnkey replacement from removal to install and disposal. This includes all types of media, including random saddles, structured media block and catalyst. In most cases we can improve on your current media design to reduce operating costs.

Spare Parts

It's critical to have the correct parts on hand when maintaining an oxidizer. We offer a large inventory of oxidizer parts that can be shipped overnight in emergency situations. We also offer an inventory management system for a no hassle spare parts solution.

Thermal Oxidizer Repair

We can provide repairs and upgrades to your existing equipment on any make or model. Our group of engineers and technicians will evaluate your problem and provide the best solution for the given situation.

Thermal Oxidizer Upgrades

As systems age so do the components. Upgrades to the PLC controls system, burner ratio control and flow control valves can extend the life of the equipment and reduce downtime. We can also upgrade existing systems to improve the thermal efficiency and destruction efficiency.

Engineering Studies

In some cases finding the correct solution to a problem requires an engineering study. Our engineers will travel to the facility and provide an in-depth review of the process. Once we’ve completed the engineering study, we’ll provide you with an engineering report including a proposal of our recommended changes for your system.

Compliance Testing

At TANN Corporation, our goal is to help reduce harmful emissions into the air. Depending on the uncontrolled Volatile Organic Compound emission rate for a specific plant, the level of VOC destruction needed to keep VOC emissions below 100 tons per year may be 95% or less.

Thermal Oxidizer Refurb

If you are looking for an economical option for the most reliable RTO in the industry, ask us about one of our inventory of used RTOs. TANN has several RTOs in stock ranging from 4,000 to 25,000 SCFM capacities and can be backed with a full warranty after refurbishment.