In 2010, TANN Corporation designed and installed a 10,000 SCFM RTO for a silicone coating line. This customer had originally installed a recuperative oxidizer, for cleaning purposes. The recuperative oxidizer had a thermal efficiency of 65% and life expectancy of 15 years. Since the oxidizer was near the end of its life expectancy, the customer considered a regenerative thermal oxidizer from TANN due to the large energy savings. In the past, RTOs have not been the first choice in silicone applications, however if designed properly the RTO can offer large energy savings while minimizing the maintenance cost.

Operating Cost Comparison

| Recupe | RTO | |

| Annual Operating Cost | $77,120 | $7,300 |

| Ceramic Media Replacement | $6,000/year | |

| Total | $77,120 | $13,300 |

| Total Savings Per Year | $63,820 |

Specifications

- 10,000 SCFM RTO

- 99% Destruction Efficiency

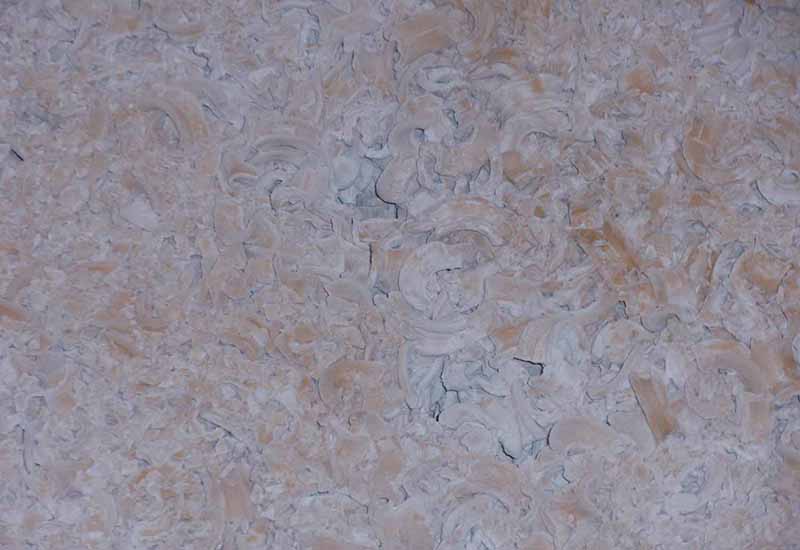

- Random Packed Saddle Media

- Additional Fan Static Pressure to

- Overcome Silicon Fouling

- Media Loading Doors

- 16% LEL Solvent Concentration

Update 2016

After 6 years of operation the 10,000 SCFM RTO is operating as expected. Media change outs are performed annually during the preventative maintenance inspection. The top 2’ of saddles are vacuumed out, and new media is added. The system has operated up to 2.5 years before requiring a change out. However, the customer prefers to change annually due to the flexibility during the inspection.

Project Photos